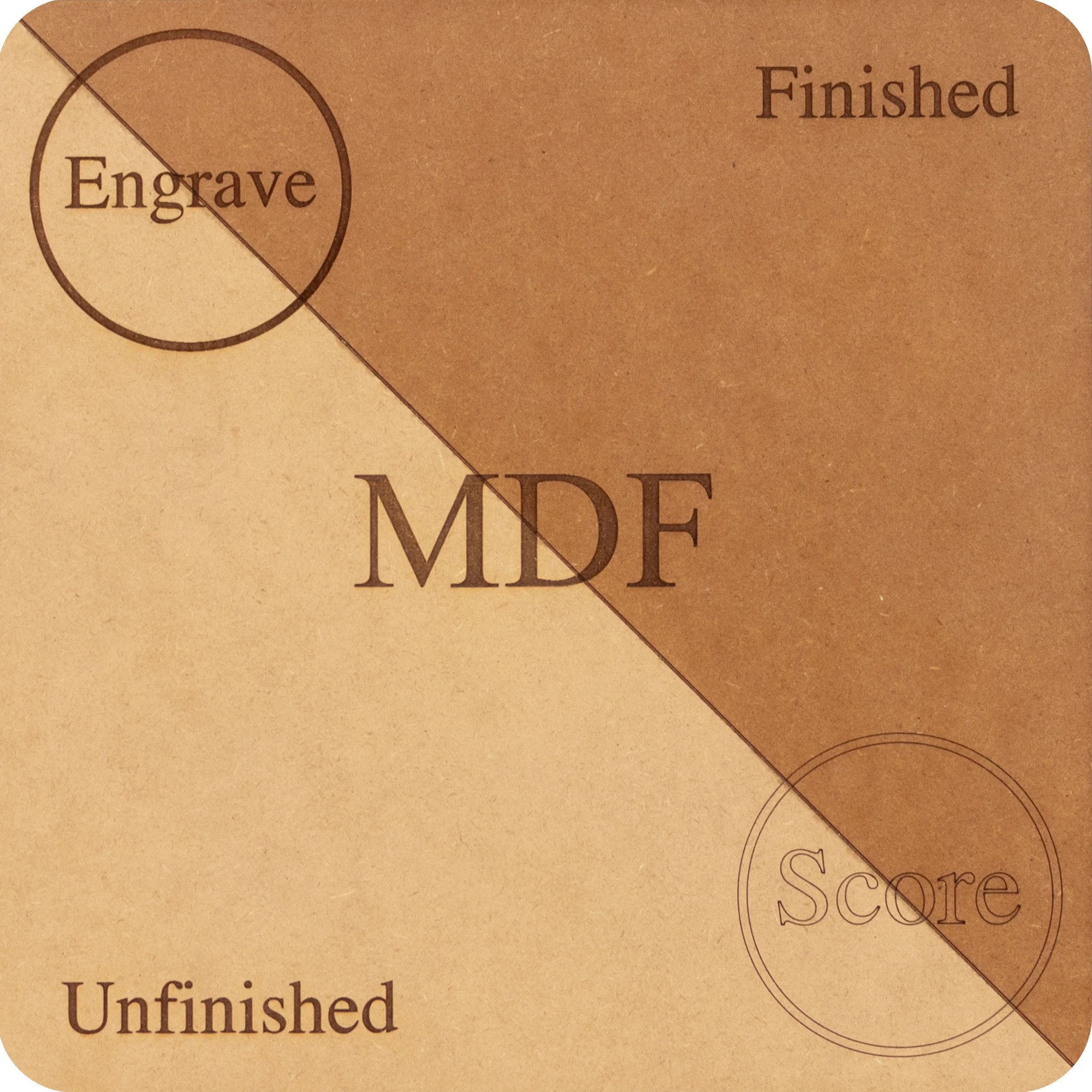

As it turns out, not all composites or medium density fiberboards are the same. Medium Density Fiberboard (MDF) is a composite material that is used for many home and business projects, like making furniture, cabinets, floors, and even speaker boxes because it is strong, consistent, and has a smooth finish.

All MDF is made in a way that is similar to how particleboard is made: wood fibers are mixed with resin, then heated and pushed together to make strong panels. But besides “regular” MDF, there are a few other types that are made especially for certain uses and fall under the MDF term.

1 MDF that bends

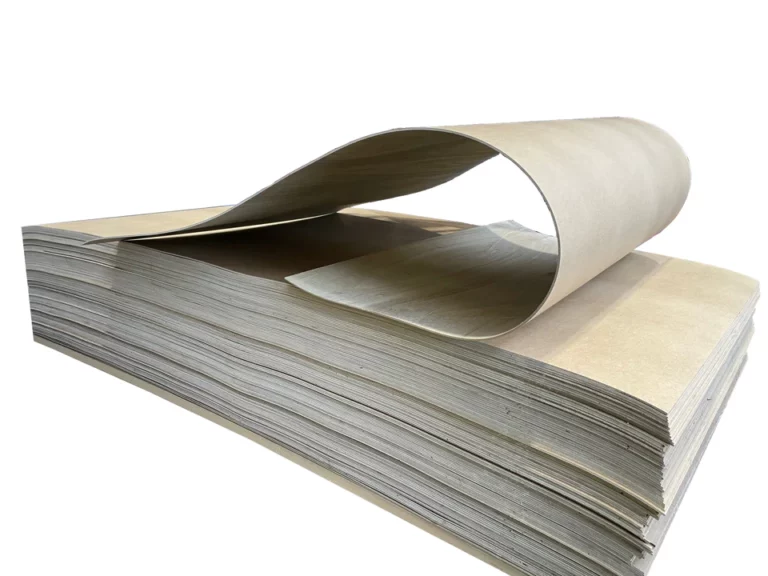

It is possible to make bendy MDF, which is also known as flexible Medium Density Fiberboard (MDF), so that the panel can bend and turn into any shape you want. It can be painted, veneered, or coated to make one-of-a-kind pieces, just like regular MDF. Architects and artists use it a lot to make pieces with dramatic slopes and curves in a lot less time and for a lot less money than when they use other materials.

2 Very light MDF

Because MDF is dense and strong, the combination is pretty heavy. This kind of light MDF, on the other hand, is only two-thirds as heavy as normal MDF. Because it’s heavy and strong, it’s perfect for projects that need to be moved around a lot, like trade show booths, theater sets, mobile homes, event setups, and “pop up” shops or galleries.

3 Not flammable MDF

A lot of places would rather (or even have to) have buildings made with fire-resistant materials. To be sure you are getting real fire-resistant MDF, the panel needs to be certified by a respected organization like UL. To follow building codes and rules, fire-resistant MDF is often used in stores, offices, and other industrial buildings. But fire protective MDF can also be used in homes to make them safer in case of a fire.

4 Sticky beads

Standard MDF is used to make beadboard, which has a fake tongue and groove pattern that is popular in wainscoting. People often use the terms “wainscot” and “beadboard” to refer to the same thing, but “wainscot” usually means any kind of half-wall wood panels. It can be made with traditional tongue-and-groove boards, but beadboard is more common because it’s cheaper. Beadboard wainscoting is often used as a design element in bathrooms, kitchens, and dining rooms in homes.

Lasercut 1/4-inch MDF for walls cutouts

Medium Density Fiberboard (MDF) is an engineered wood product that can be used in a lot of different ways inside, for things like furniture, cabinets, and artistic elements like wall cutouts.

Many people choose 1/4-inch MDF for making wall cutouts because of its special qualities.

1/4-inch MDF is a moderately thick material that strikes a mix between strength and flexibility. This thickness makes it good for wall cutouts of different shapes and sizes; it’s stable enough to keep the structure together while still letting you add fine details.

One of the best things about using 1/4-inch MDF for wall cuts is how easy it is to make changes. It is easy to cut and shape MDF because it has a smooth surface and a consistent stiffness. Whether you’re making unique lettering, geometric patterns, or floral motifs, 1/4-inch MDF lets you make complex designs with smooth edges that make your space look better.

1/4-inch MDF is also lighter than thicker materials like solid wood or plywood, which makes it easier to work with and install. This is especially helpful for people who like to do their own projects or for projects where weight is an issue. It makes fitting easier without lowering the quality.

Fine Laser Cutting with 1/4-Inch MDF

When it comes to making wall cutouts with detailed designs and fine details, laser cutting technology and 1/4-inch MDF give you the most accuracy and precision. Laser cutting works by shining a strong laser beam onto the MDF surface. The beam melts or vaporizes the material, making clean cuts with a small kerf width.

Combining laser cutting with 1/4-inch MDF makes it possible to make designs, shapes, and small details that would be hard to get with other cutting methods. Laser cutting is very accurate, so the sides and curves are always smooth. This makes the wall cutouts look better.

Also, 1/4-inch MDF that has been laser-cut is consistent and repeatable, which makes it possible to copy complex patterns very accurately. Laser-cut 1/4-inch MDF gives you the best quality and precision when making custom wall art, decorative panels, or architectural accents. It makes any place look better.

Comparing 1/4-inch MDF to Other Types

Before you decide to use 1/4-inch MDF for wall cutouts, you should make sure you know how it compares to other types on the market. There may be pros and cons to choices that are thicker or thinner, but 1/4 inch MDF has a unique balance of qualities that make it perfect for wall cutout projects.

1/4 inch MDF is lighter than thicker types of MDF like 1/2 inch or 3/4 inch, which makes it easier to work with and install. This also means that less material is needed, which saves money without lowering the grade. Also, 1/4-inch MDF is stable and strong enough for most wall cutout designs, and it can be customized and detailed in a lot of ways.

On the other hand, 1/4-inch MDF is more durable and stable than smaller types of MDF, like 1/8-inch or 1/16-inch. Thinner MDF may be more likely to warp or break, especially in wall cuts that are bigger or more complicated. 1/4-inch MDF, on the other hand, is a good mix of stability and flexibility.

As a whole, 1/4-inch MDF is the best choice for wall cutouts because it has a thickness, strength, and customization options that make it suitable for a wide range of design projects.

Conclusion

Medium Density Fiberboard (MDF) is a versatile composite material used in various home and business projects, including furniture, cabinets, floors, and speaker boxes. MDF is made by mixing wood fibers with resin, heating, and pushing together to create strong panels. There are several types of MDF, including bendy MDF, which allows for dramatic slopes and curves, very light MDF, which is heavy but only two-thirds as heavy as normal MDF, not flammable MDF, which is not flammable but requires certification from a respected organization like UL, moisture-resistant MDF, and sticky beads.

For wall cutouts, 1/4-inch MDF is a popular choice due to its unique qualities. It is moderately thick, making it suitable for various shapes and sizes, and easy to cut and shape. It is also lighter than thicker materials like solid wood or plywood, making it easier to work with and install. Laser cutting technology can be combined with 1/4-inch MDF for precise and accurate designs, shapes, and small details.

When choosing 1/4-inch MDF for wall cutouts, consider its thickness, strength, and customization options. It is lighter than thicker types, making it easier to work with and install, and more durable than smaller types. However, thinner MDF may be more likely to warp or break, especially in larger or more complicated cuts. Overall, 1/4-inch MDF is the best choice for wall cutouts due to its balance of stability and flexibility.

-

Feather Wall Hanging

$115.00 – $235.00 Select options This product has multiple variants. The options may be chosen on the product page

Female Floral 2

$55.00 – $150.00 Select options This product has multiple variants. The options may be chosen on the product page

Feather Wall Hanging 2

$90.00 – $205.00 Select options This product has multiple variants. The options may be chosen on the product page